X5W

Designed for heavy-duty, high-demand applications.

500A CO2 @ 100% Duty Cycle

450A Mixed Gas M21 @ 100% Duty Cycle

Shielding Gas Flow Rate: 16-22 l/min

Volume Flow Rate: Fume Nozzle 66 m3

X5W – Liquid-Cooled High Performance Mig Fume Torch

Designed for heavy-duty, high-demand applications, it ensures high-efficiency fume

capture at the generation point, minimizing airborne contaminants.

Make Work Life Easier

Massive Gains in Productivity!

Arc Wear Parts are more efficient and last longer!

- Contact tips last up to 6 times longer

- Nozzles last up to 3 times longer

- Tip adaptors last up to 5 times longer

Technical Specification

| Cooling Method | Air-Cooled | Max. Load |

|---|---|---|

| Rating: CO2 | 500A | 20.0KW |

| Rating: Mixed Gas M21 | 450A | 17.1KW |

| Duty Cycle | 100% | |

| Wire Size | 0.9-1.6mm | |

| Volume Flow Rate: Fume Nozzle | 52 m3h | |

| Volume Rate: Connector | 66 m3h | |

| Pressure Drop | 10 kPa | |

| Shielding Gas Flow Rate | 16-22 l/min | |

| Efficiency | 93% | |

| Minimum Liquid Flow Rate | 1.5 l/min | |

| Minimum Liquid Inlet Pressure | 2.5 Bar | |

| Maximum Liquid Inlet Pressure | 5.0 Bar | |

| Maximum Liquid Inlet Temperature | 50oC | |

| Operating Temperature Range | -10..+40oC |

Downloads

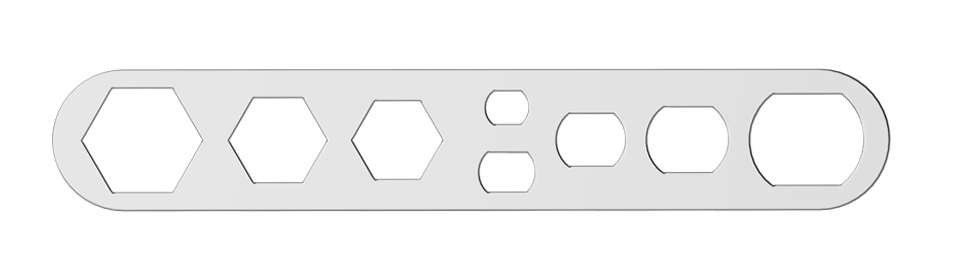

Key Elements

Core Technologies

In The Box

Standard Set-up